Single Family Project of the Year

Home on Chisholm Place, Charlottesville, VA

Promethean Homes

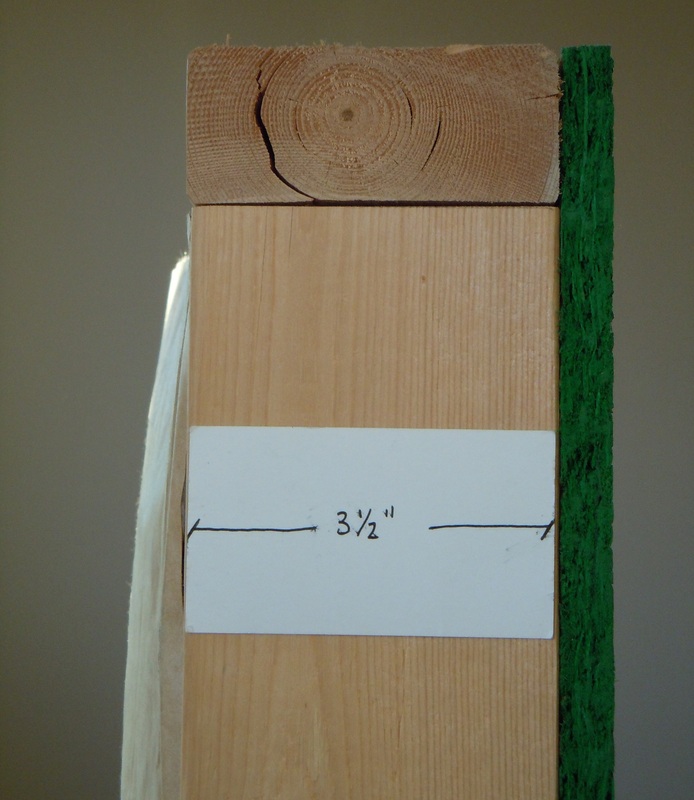

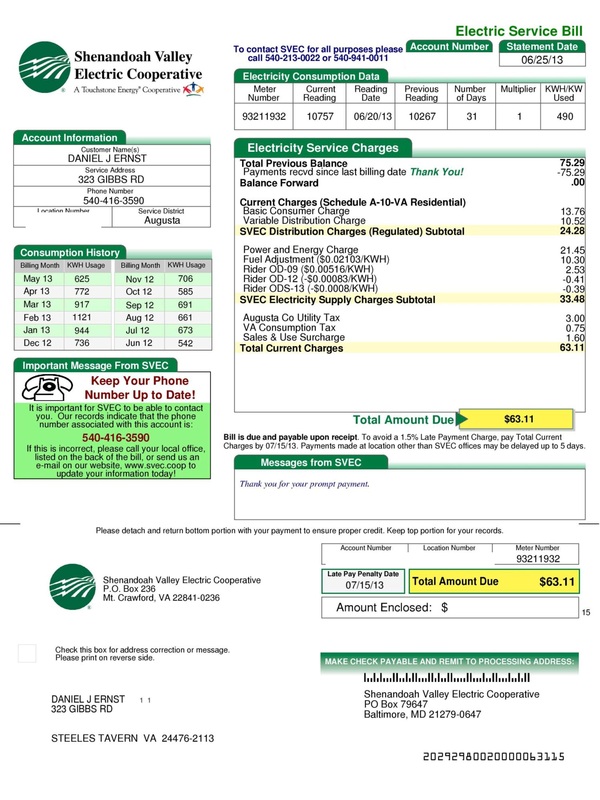

Promethean Homes’ Chisholm Place project scored a 33 on the HERS Index (without any renewable energy generation!), achieved EarthCraft Platinum certification, the highest certification level possible, and ranked 5th for the top ten most energy efficient EarthCraft homes in VA in 2014. The house won a DOE's Zero Energy Home Challenge as well as certified as Energy Star, EPA WaterSense and Indoor airPLUS. Promethean used a number of leading edge methods and technologies including nearly air-tight construction with a blower door test result of just 0.02 cfm50/ft2, super-insulated walls (R-30), slab (R-16) and ceiling (R-67), along with triple pane windows. The HVAC system features two, high efficiency ducted mini-split heat pumps, along with a high efficiency ERV for whole-house ventilation. Water heating is provided by a heat pump water heater, all appliances are Energy Star certified, and nearly all lighting is LED. Daniel Ernst, Promethean Homes, accepted the award.

You can read about other great projects and award winners here:

http://www.earthcraftvirginia.org/events_annual/earthcraft-virginias-sustainable-leadership-awards/

RSS Feed

RSS Feed