With this simple tool it is easy to see where the insulators did a poor job, or where an electrician installed a recessed can light. And you certainly don't need a stud finder to see the location of the studs and rafters.

RADIATION

No, we're not talking about nuclear energy. Think of fire or sunlight. Even though the air temperature near a fire might be cold, you will still feel very warm when you sit directly in front of that fire. This phenomenon is known as radiant heat flow. In buildings, we don't really worry about this to much, but we do consider it when we think about windows and roofs (i.e. unshaded west facing window).

CONVECTION

Think air. Think movement. Think of a leaky window on a cold and windy day. Can you hear it whistling? A lot of heat will move out of your house in this way, hitchhiking a ride on the air that is flowing outside. For most houses, this is one of the dominant forms of heat transfer (loss or gain, depending on the season). Convective heat transfer is why air barriers are so important.

CONDUCTION

This one is fairly easy to understand. It occurs when heat flows through a material. Metals are great conductors, so heat flows through them very easily. That's why we use them for cooking, right? In houses, conduction is another important form of heat transfer.

When we talk about houses and conduction, we start looking for something called a thermal bridge. Remember, heat is lazy. It follows the easy way out. A thermal bridge is that easy path. It is a solid and direct connection between the interior and exterior of the building.

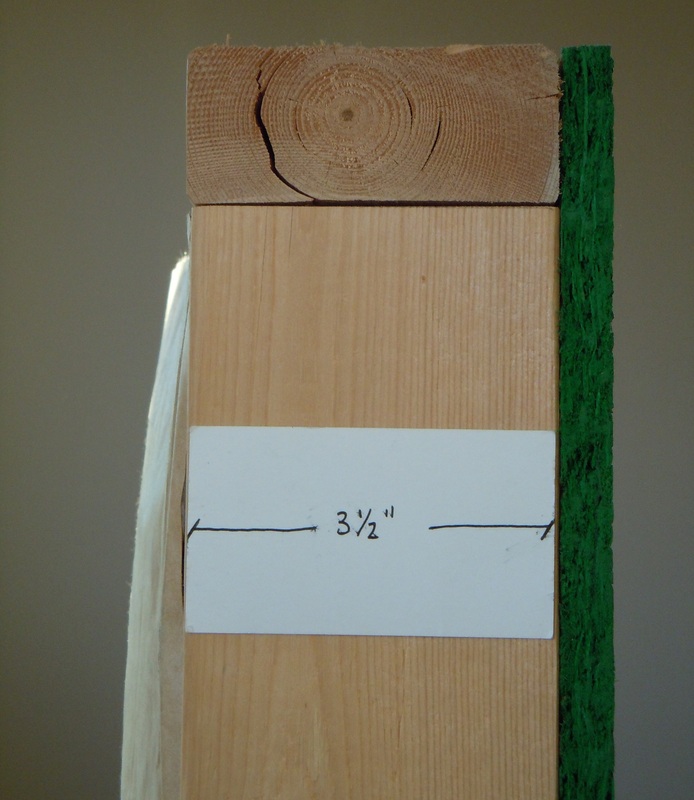

In Virginia, most houses are built with 2x4 stud walls.* These studs span from the inside, where they are attached to drywall, to the outside, where they are attached to the sheathing. And although we don't think of wood as a great conductor, on hot or cold days, these 2x4 studs become an interstate highway for heat flow.

Or two, a builder can create a double-stud wall (one is structural, the other is non-structural). The studs in this kind of wall do not span from the inside to the outside; there is a gap between them that is later filled with insulation.

Either method creates a thermal break---instead of a thermal bridge---and makes it that much harder for heat to flow. As a homeowner, you get greater comfort and lower energy bills.

*For the historically minded, this type of construction dates back to the late

1800's, and is partially a result of the Great Chicago Fire of 1871. Rebuilding

efforts stimulated the search for quick and cost effective framing systems. 2x4

lumber met the minimum structural requirements for two-story residences. Throw in some machine drawn nails, and you have the birth of modern-day framing systems. We have since transitioned from balloon framing to platform framing, but stud sizes have remained fairly consistent for > 125 years.

RSS Feed

RSS Feed